A Guide to Swimming Pool Wave machines and the Use of Control Panels

Watching waves roll in and break on the beach is an example of a transfer of energy from wind, to water to land. Waves are created when wind blows across water, which over time causes the water to rise up and down and eventually to start circulating. The harder the wind blows and the longer it blows for then the greater the amount of energy transferred, and hence the bigger the wave created.

When waves encounter shallower water, then the wave will break, creating the opportunity for surfing or just having fun on the beach.

In a world where many people are time poor and have constrained leisure time, waiting for the right natural conditions to occur to create perfect waves for their enjoyment isn’t always an option. This is where a wave machine comes into its own.

What Is a Wave Machine For?

A wave machine is a means of putting energy into water in a controlled manner to create a wave, typically in a pool, a lagoon or river environment. The geometry of the environment together with the way in which energy is imparted into the water allows different types of wave to be created.

The are a range of different ways that wave machines can put energy into water, these include

Types of Wave Machine

Air Blowers – water is moved around via the rapid, powerful pumping of air, this process is tightly controlled across multiple air blowers to create a range of different wave sizes and forms.

Water Dumping – a reservoir tank is used to accumulate a large volume of water which can then be dumped into a designated location in a waiting pool, this sudden influx of water displaces an equivalent volume of water which in turn creates a wave that travels down the pool. The size of the wave is controlled by the volume dumped into the pool. The operation of the system is controlled via a series of valves, pumps and interconnecting pipes to ensure that the required volume of water is ready to be dumped at the right time.

Hydrofoils – typically found in a lagoon, an underwater foil is pulled rapidly through the water, the movement of this foil displaces water above it which in turn creates a wave. The geometry of the foil relative to the lagoon, and the speed at which the foil is pulled changes the size and shape of the wave created. Powerful motors are required to move the foil at the appropriate speed.

Mechanical push plates – waves are created by motors pushing a series of plates mounted inside a module mounted in the water. Depending on the pattern in which the plates are made of, then the size and shape of the resulting wave can be changed.

The Importance of Control

Having the mechanical means to move water around is only part of the challenge, the way in which the water is moved has to be tightly controlled in order to create the right wave at the right time. This is why a control panel is an essential element of the system.

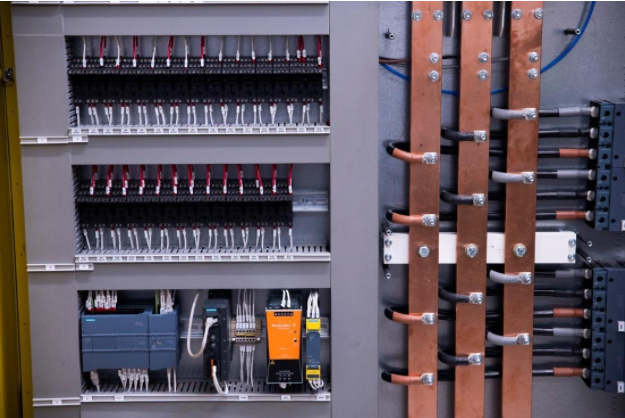

Each type of wave creation system features many components, typically including motors, actuators, pumps and sensors, the operation of these different elements is integrated into a control panel which generally features a PLC with a complex programme running on it. The different types of waves are created by selecting from a range of programmes stored on the PLC. These programmes can be initiated via simple switches on the control panel or via a more complex HMI screen connected to the PLC.

Energy Efficiency

Another consideration is that moving water around is an energy intensive process, hence optimising the operation of the system through the use of variable speed drives to control pumps is essential. Likewise, the power requirements of a system can be high, meaning that a safe, reliable control panel is a must for any wave machine manufacturer.

For Wave Machine Control Panels Contact Us Today

Bensons has a rich heritage in the design and build of wave machine control panels, our panels can be found in settings in over 30 countries around the world, providing reliable, cost-effective operation year on year. Since we create the PLC programmes ourselves, we are able to support the maintenance and up-grade of systems as and when the need arises.

Celebrating ISO9001 Audit Success - and why it matters to our customers

We’re delighted to share that Bensons Panels has successfully passed our latest six-monthly ISO9001 audit, this one had a particular focus on our manufacturing processes and systems.

Five tips for a High-Quality Control Panel Enquiry

At Bensons Panels, we believe that great projects start with great conversations. The early conversations that come at the enquiry stage can shape the outcome and character of the whole project.

Investing in Expertise – The Added Value from Working with Bensons Panels

Choosing the right control panel partner is an important decision, one that can shape your project’s immediate success, but also the ongoing efficiency and reliability of the system that the control panel is integrated into.

Leeds Manufacturing Festival 2025

On 12th June, Bensons attended the Leeds Manufacturing Festival (LMF) annual awards, this year hosted at Leeds Beckett University, to celebrate the champions of the industry.

Need to discuss your perfect Control Panel solution? Simply fill in the form with your details and requirements and we'll be in touch!