5 Benefits of PLC Control Panels

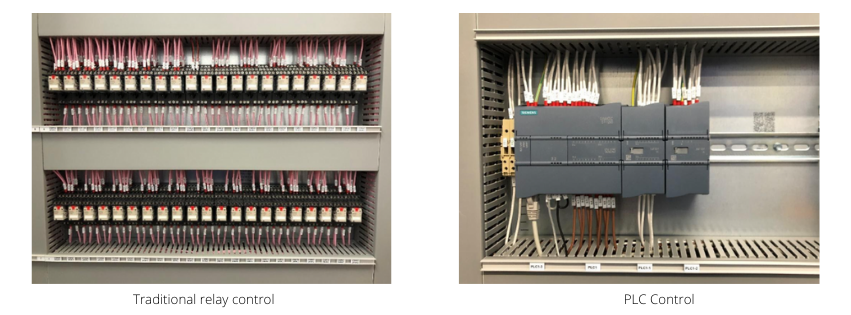

Programmable Logic controllers (PLCs) are small, industrial computers, developed to control a range of processes in industrial settings. They can deliver a more flexible and advanced level of control than traditional hard-wired relays and timers.

PLCs were first introduced in the automotive sector in the late 60’s with the aim of replacing hardwired relays and timers with programmable and flexible controllers. Since their introduction, the capability of PLCs has grown significantly in line with progress in personal computing and software developments. Whilst the basic principles are the same, the capabilities of modern PLCs are unrecognisable compared to the original systems.

Whilst most control panels still feature an element of relay control, Bensons builds many advanced control panels each year which include PLCs providing our customers with the advance control that they need to operate their complex systems. In this article we have sought to summarise the key benefits that these PLC control panels offer.

More Performance, Less Space

PLCs offer a robust means of delivering complex control based on complex computation, capable of acting on inputs from the many devices and sensors found in modern, industrial settings. Since the logical operations previously carried out by relays and timers are now managed in software, the physical space within a control panel required to provide this control is reduced, in turn saving space on site. In addition, the computational power of the PLC means that much more advance control can be achieved than would previously have been the case.

Communication

PLCs can provide the ability for a system to be monitored remotely, providing detailed information on the performance of a system, or condition monitoring data to a central control location. This location could be in the same building or hundreds of miles away. By using this capability, the operator can maximise the performance of their system without the need to be physically present.

For those occasions when physical interaction is required, then PLCs can be used to control displays mounted on the control panel, providing an advanced human machine interface (HMI) to de-bug, monitor and improve the performance of the control panel in-situ. PLCs can also be networked, allowing the performance of the control panel and the system it controls to be monitored

Reliability

Once software has been written, debugged and tested it will run reliably with no degradation over time due to the aging of components. As such, systems controlled by PLCs offer greater reliability than their predecessors. In addition, the reduced number of electrical connections provide less opportunity for error in manufacture and commissioning.

Flexibility and Maintainability

The requirements of industrial applications often develop over time with system improvements and up-grades. Having a software-based control solution provides greater flexibility to accommodate developments, wiring changes can be minimised and downtime reduced. In addition, the ability for PLCs to communicate with other systems can allow software up-dates to be implemented remotely. Debugging of changes is also simplified, since the programme can easily be downloaded and visualised by the engineers responsible.

Reduced Cost

Where multiple versions of the same system are deployed, cost can be saved through the reuse of software. Once a programme has been developed and proven to work on the first implementation of a system, it does not need to be re-written on subsequent implementations of the same system. Such repeatable control can be delivered for just the cost of the hardware elements of the system.

For Reliable Electrical PLC Control Panels, Contact Us Today.

At Bensons, our PLC control panels are used to deliver complex functionality in a range of industrial settings. We design our control panels around the PLC to allow the delivery of optimal control.

To find out more or to tell us about your project, please get in touch on 01924 975494.

Celebrating ISO9001 Audit Success - and why it matters to our customers

We’re delighted to share that Bensons Panels has successfully passed our latest six-monthly ISO9001 audit, this one had a particular focus on our manufacturing processes and systems.

Five tips for a High-Quality Control Panel Enquiry

At Bensons Panels, we believe that great projects start with great conversations. The early conversations that come at the enquiry stage can shape the outcome and character of the whole project.

Investing in Expertise – The Added Value from Working with Bensons Panels

Choosing the right control panel partner is an important decision, one that can shape your project’s immediate success, but also the ongoing efficiency and reliability of the system that the control panel is integrated into.

Leeds Manufacturing Festival 2025

On 12th June, Bensons attended the Leeds Manufacturing Festival (LMF) annual awards, this year hosted at Leeds Beckett University, to celebrate the champions of the industry.

Need to discuss your perfect Control Panel solution? Simply fill in the form with your details and requirements and we'll be in touch!