Centrica

How Benson’s Space-Saving Panel Design Helps Centrica Deliver CHP Solutions

The Challenge

To develop a new style of CHP Solutions in a restricted space

In this instance, the configuration and size of the engine imposed

significant space constraints within the standard sized containers

required by Centrica. At the same time, Centrica required all the

functionality of a conventional control panel, together with the

high-current switching capacity of a large Air Circuit Breaker (ACB).

The Solution

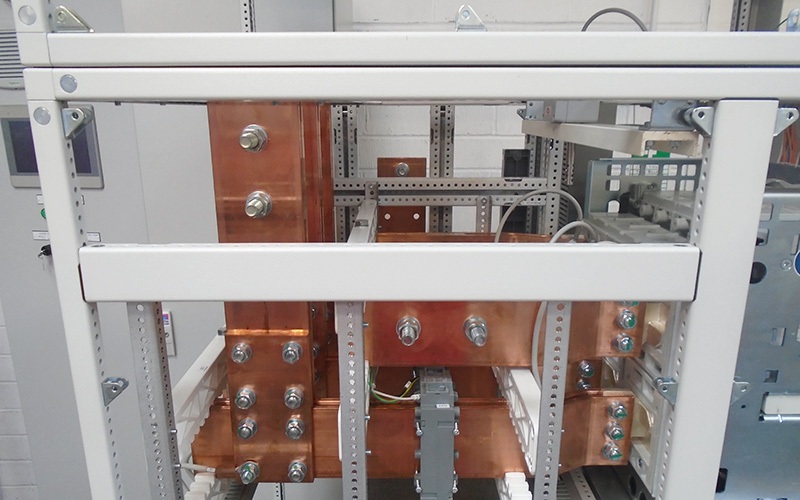

A bespoke enclosure design to work as a stand-alone item

As the panel plantroom within the container was not long or wide

enough to house the control panel in one straight line, the challenge

was to create a bespoke design to solve the space restrictions.

The Result

Space Saving | Simplified Installation | Reduced Assembley and Testing Time

With Benson’s space-saving design, the floor area within the

containerised plant room is optimised, allowing Centrica to provide a

spacious and safe working environment both for its own engineers and its

client’s engineers.

Download Case Study

Watch Video