The importance of using the right cable

Cable is cable, right? Wrong... let us explain...

At Bensons, we use around 350km of cable each year, and if it were all just one size and colour, then that would be great, but that would also be too easy. Currently, we have around 80 different types of cable in stock to support the many customers we collaborate with across multiple sectors.

This begs the question of what the differences are. And why does it matter?

Why it matters ultimately comes down to clarity, certainty, and safety. The type and colour of cable is a visual language for panel builders and equipment installers.

Within a control panel, a cable will either distribute power or allow devices to communicate. The size, colour, and material used will allow it to present information to whoever is working on the control panel.

Colour

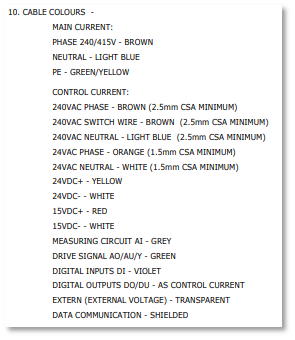

A good set of wiring diagrams will make clear what each different colour of cable does - a good panel builder will ensure that this is followed religiously. These requirements change from customer to customer and from job to job. In many cases, colours are standard across projects; for instance, since 1977 in the UK, the earth cable is green and yellow. There may be variations on this (sometimes there is a need for a clean earth cable, which will be a different colour). Beyond earthing, the colours of cables are generally down to the customer or project specifications. Amongst the more specific project specifications is the following, which provides much for the panel wirer to keep in mind whilst working.

Size

Compared with the varied colours of cables, the diameter is relatively straightforward; the higher the current carried by the cable, the bigger the diameter needs to be. Cross-sectional areas are derived from well-established specification tables and calculation methodologies.

The challenge is that the bigger the diameter, the harder the cable is to manage. At a certain diameter, it becomes extremely challenging to run a short length of cable between two termination points, leading to the introduction of 'pigtails' to simplify the process. This means that although you use more material, you save time.

Alongside different colours and different sizes, many different types of cables are used in the control panels that we manufacture. Some of the more common types include:

Tri-Rated Cable

As the workhorse for most panel builders, tri-rated cable is used on the majority of the control panels that we manufacture, unless specified otherwise. 'Tri' in the title means that it meets the standards of three different regulatory bodies: the British Standards (BS), specifically BS6231, Underwriters Laboratories (UL) in the USA, and the Canadian Standards Association (CSA) in Canada. It's able to withstand high temperatures (typically up to 105⁰C for continuous use), making it a good choice for electrical control panels and switchgear. Ensuring that the correct diameter is selected will reduce the risk of having to operate at higher temperatures - a cable in a well-designed system should never get close to 100⁰C.

Low Smoke and Fume (LSF)

Designed to minimise smoke and toxic fumes during a fire, often through the inclusion of additives in the PVC insulation to reduce smoke and hydrogen chloride (HCI) emissions. This change in the insulation can lead to a slightly chalky texture and a stiffer cable, making it harder to work with. Note that the LSF cables are not the same as LSZH cables.

Low Smoke Zero Halogen (LSZH)

A step up from LSF cables are LSZH cables, which are generally used in applications where smoke emission and toxic fumes could pose a risk to human health and essential equipment in the event of a fire. These are frequently specified for the wiring of equipment fitted indoors, particularly in public areas, and in poorly ventilated environments. This can include hospitals, schools, cinemas, stations, and leisure centres.

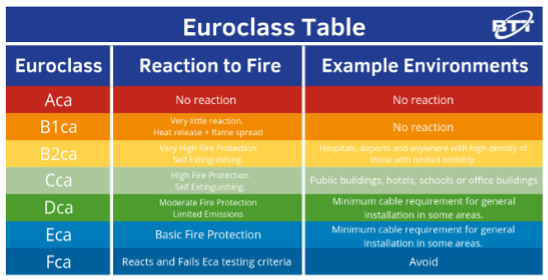

CCA and DCA Cable

These are cable types that link to the Construction Products Regulations (CPR). CPR covers the different aspects of products used in the construction industry, and in particular, what happens when they are exposed to fire. To be CPR compliant, suppliers have to declare the fire performance of each cable using Euroclass grading (see below). At Bensons, we typically see CCA and DCA cables on data centre projects.

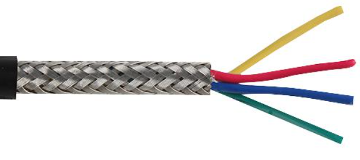

Screened Cable

Screening of a cable means putting aluminium foil and/or copper braid around the conductors to protect the data travelling within the conductors from electromagnetic interference.

Often used for the wiring of analogue inputs and analogue outputs, where clear and accurate signals that are free from interference are needed for reliable operation. The number of cores in a cable can vary from two up to 'lots', with 12-core not being that uncommon. From a panel builder's perspective, stripping back the braid and connecting it to earth is a skilled process that can be both time-consuming and laborious. When balancing time vs. materials, it pays to have a more expensive cable that is easier to strip and work with, meaning less rework and a more productive (and happier) wirer.

The happiness of your wiring team appears to be inversely proportional to the quantity of screened cable in a panel, and the number of cores.

Double Insulated Cable

This is a cable type with two layers of insulation between the live cores and the outer casing, providing a backup in case one layer fails. At Bensons, we use orange double-insulated cable on the live side of any power circuits. It was having to commit to a minimum order quantity of 5km (yes, kilometres) of orange double-insulated cable that prompted this article. This quantity of cable will last several years, but it means we and our customers know the right cable is fitted for the right application.

Hopefully, this article makes a start at explaining the complexity and importance of selecting and using the correct cable for a given panel on a given job.

Alongside the points raised above is the challenge of selecting a cable that is easy to work with. This is not always the same between manufacturers and is important for the productivity of the wiring team. Key considerations include the flexibility of the cable, how easy it is to strip the insulation from, the consistency of colour matching between reels, and whether the cable has any 'memory'. If the cable possesses memory and doesn't lie flat and straight, for instance, holding its curve from being wound onto a reel, then it can become unusable, increasing scrap levels.

Celebrating ISO9001 Audit Success - and why it matters to our customers

We’re delighted to share that Bensons Panels has successfully passed our latest six-monthly ISO9001 audit, this one had a particular focus on our manufacturing processes and systems.

Five tips for a High-Quality Control Panel Enquiry

At Bensons Panels, we believe that great projects start with great conversations. The early conversations that come at the enquiry stage can shape the outcome and character of the whole project.

Investing in Expertise – The Added Value from Working with Bensons Panels

Choosing the right control panel partner is an important decision, one that can shape your project’s immediate success, but also the ongoing efficiency and reliability of the system that the control panel is integrated into.

Leeds Manufacturing Festival 2025

On 12th June, Bensons attended the Leeds Manufacturing Festival (LMF) annual awards, this year hosted at Leeds Beckett University, to celebrate the champions of the industry.

Need to discuss your perfect Control Panel solution? Simply fill in the form with your details and requirements and we'll be in touch!