Productivity Improvement Activities at Bensons

Productivity Improvement Activities at Bensons

Why did we do it

In order to remain competitive in an increasingly challenging marketplace, it is essential for manufacturers to work productively. The ability to deliver value to customers in a cost-effective manner is fundamental to a sustainable business. Productivity improvements can typically be achieved by investing in capital equipment, manufacturing processes or people.

As a skills-based business, and following feedback from our first employee engagement survey, Bensons elected in late 2021 to invest in our people and processes with the aim of improving our organisational productivity:

- To provide opportunities to our workforce for career progression within Bensons. Better that they progress their careers with us than with someone else

- To improve our productivity, allowing us to be more competitive in the market place

- To make it easier for everyone to do a great job, fix problems as opposed to continually work around them

In addition to the point raised regarding limited opportunities for career progression, we identified that whilst we consistently build control panels to a high level of quality, we had developed a habit of working around problems instead of fixing them. Hence, we wanted to bring in a cultural change focused on problem solving to minimise expensive re-work, and improve productivity.

What did we do

- Developed an idea internally to create four new positions as ‘manufacturing champions’ within the business, to provide leadership in each of the production areas

- Found a partner organisation to work with to provide the skills and training needed

- Provided a structured, hands on training programme to each of these people, together with a ‘buddy ‘ in each area so as to ensure that they had the skills and support needed

- Implemented a 12-week training programme

Through collaboration with Leeds Beckett University on a collaborative R&D project in 2019 and 2020 we had exposed some of the business to lean manufacturing techniques and the concept of continuous improvement. We had also been introduced to Fluere through this project and felt they would be a good fit with what we wanted to do.

We kicked around some ideas with Paul Molloy, the MD of Fluere, to tailor their ‘Team Leader’ training programme to Bensons

For the people that we wanted to develop it was important that we established the best learning approach for them – it had to be practical, hands on and relate to Bensons.

How did we do it

- Realised that we didn’t have the skills or bandwidth to do this ourselves and needed some external help

- Identified a partner to support us

- Mapped out an approach to create ‘Manufacturing Champions’ within the business,

- Developed a project proposal

- Secured funding from the Manufacturing Growth Programme and the Strategic Growth Programme

- Bensons matched the funding from MGF and SGF

- Briefed out to the team and secured volunteers

- Deployed a 12wk programme, led by Steve Lowrey from Fluere

A key piece in making sure that the activity was a success was to have engagement of our team members. If it was ‘something we were all doing together’ then it would work more effectively.

We briefed out the concept to everyone in the company, and invited people who were interested to nominate themselves for the role. This was an ‘opt in’ process and no-one was forced to attend.

With the funding investment and the dedicated time on site from Steve at Fleure, this was a process of learning through doing, i.e. Fluere did not give us the answer, rather they taught our people the skills that they need to develop their own solutions. We taught our people how to fish, as opposed to providing them with fish to eat each day.

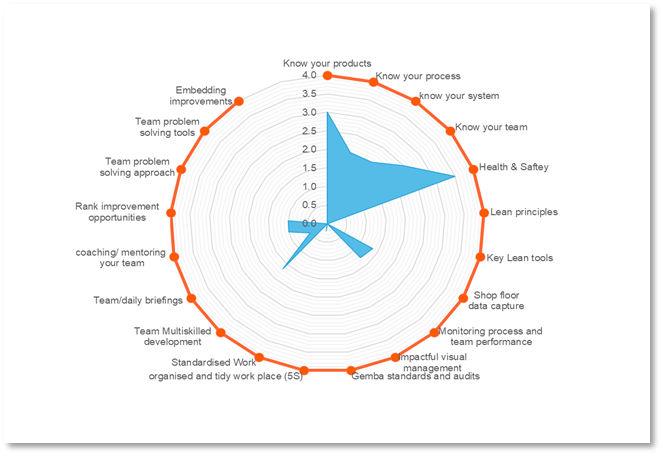

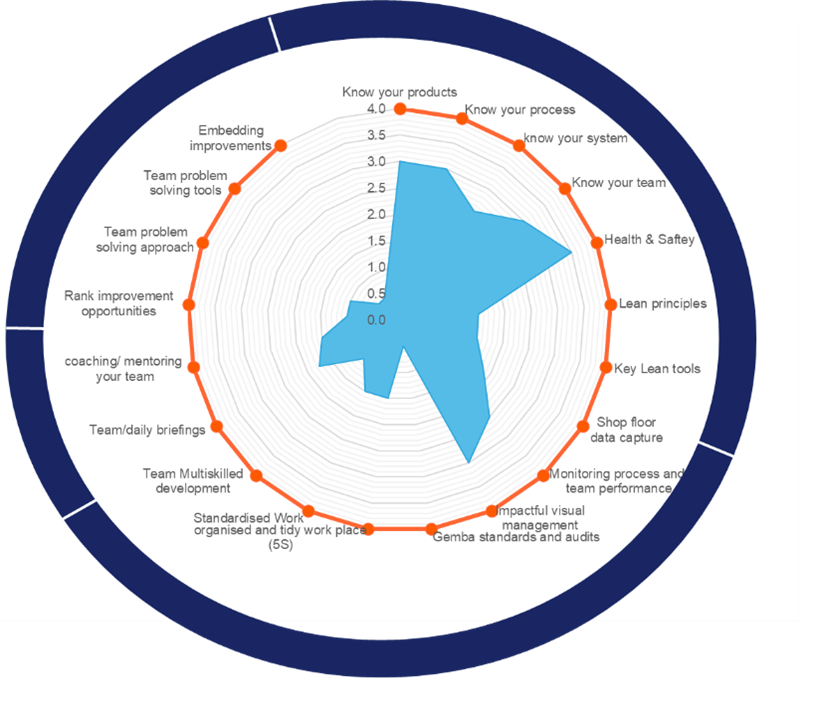

Our manufacturing team and processes were audited by Fluere before and after the activity so that we had data points to refer to and could see where and by how much we had progressed.

Audit 1 – Key Points Before

Key areas of programme content introduced some key lean concepts:

- 5S

- 8 Wastes

- Key Performance Indicators

- The importance of product flow through a factory

- Standard Operating Procedures – “One best way”

Working with the team we developed our existing KPIs so that we could look at key inputs and outputs from each part of the production process to start to measure our performance from end to end. This provided us with data to make decisions as to where best to target our improvement efforts. KPIs are shared openly with all members of the production team and performance is briefed out each week

A pilot production area was chosen for which to develop a comprehensive set of SOPs to then be used as reference for the rest of the company. This paid back massively when a combination of covid and holidays meant that we lost the entire team for a few days - having fully documented procedures meant this key stage of the manufacturing process could keep going using resource from the rest of the factory.

Process flow was demonstrated through the well known lean training tool “the plug game” which uses the assembly of 3-pin plugs to demonstrate various production principles.

Audit 2 – After. Though this is not the finished article, it demonstrates visible progress

Impact and Sustaining Change

Impact

- We have identified manufacturing champions and provided them with the skills to be a focal point for continuous improvement within our manufacturing process.

- We have started our journey towards improving productivity.

- Robust set of KPIs that allow us to monitor our performance and target where we want to focus our efforts

- We are seeing improvements in productivity

Sustaining the change

- During the training programme we recruited Mathew Orme as manufacturing manager. He brings with him a wealth of expertise and experience in manufacturing and CI and has taken on the programme and developed it further.

- We share all KPI information (good and bad) with the team weekly so they are all aware of performance.

- Dedicated time set aside each week for manufacturing champions to work on the business as opposed to in the business.

- Investment in tools and equipment as required.

- Roll-out of the CI concepts taught to Manufacturing Champions to the rest of the business, so that we all speak the same language.

We will continue to monitor our progress and will take a further audit down the line.

Celebrating ISO9001 Audit Success - and why it matters to our customers

We’re delighted to share that Bensons Panels has successfully passed our latest six-monthly ISO9001 audit, this one had a particular focus on our manufacturing processes and systems.

Five tips for a High-Quality Control Panel Enquiry

At Bensons Panels, we believe that great projects start with great conversations. The early conversations that come at the enquiry stage can shape the outcome and character of the whole project.

Investing in Expertise – The Added Value from Working with Bensons Panels

Choosing the right control panel partner is an important decision, one that can shape your project’s immediate success, but also the ongoing efficiency and reliability of the system that the control panel is integrated into.

Leeds Manufacturing Festival 2025

On 12th June, Bensons attended the Leeds Manufacturing Festival (LMF) annual awards, this year hosted at Leeds Beckett University, to celebrate the champions of the industry.

Need to discuss your perfect Control Panel solution? Simply fill in the form with your details and requirements and we'll be in touch!