How do you implement an ERP system in an SME?

How do you implement an ERP system in an SME?

Having accurate information with which to run a business has never been more important, without good data and the insight drawn from it, decision making is all to often based on gut feelings and optimism.

Back in 2018 it became apparent to us that whilst Bensons had a glut of data upon which to base decisions, there were a few problems with it:

- Much of it was siloed, meaning it was difficult to associate cause and effect resulting from any improvement activities that we undertook;

- Our data wasn’t available in a timely fashion; and,

- Some of the accuracy was questionable, given its heavy reliance on manual entry and workarounds.

Whilst the business had run successfully up to this point, this wasn’t a recipe for success in terms of scaling Bensons; ‘something had to be done’. This is what led us down the Enterprise Resource Planning (ERP) route.

The aim of this article is to share our learnings from the implementation of an ERP system in an SME, there is a wealth of information out there about different systems available, however we found precious little information about how to implement and ERP in an SME.

ERP stands for Enterprise Resource Planning, depending on which definition you take this is essentially the integration of the main business processes and applications in a single, software solution. At a full implementation this can encompass HR, CRM, supply chain, services, procurement and accounts. But let's not get ahead of ourselves.

Having decided that ‘something had to be done’, we then had to establish what that ‘something’ was. Our approach was based on five steps:

- Work out what you want to achieve;

- Find the solution that offers the best fit;

- Agree how to deliver the solution;

- Have a plan, and follow it; and,

- Transition to using the ERP solution.

Work out what you want to achieve

We boiled ‘something’ down to alleviating material shortages by aligning component stock levels to production requirements. This in turn would make us a more productive manufacturer, since working around missing parts and chasing suppliers for them is a time consuming task which adds no value to the customer. In addition, we wanted to automate the capture and processing of the hours that we work on each job that we do. This would replace a manual, legacy system that was no longer supported by the supplier.

Find the solution that offers the best fit

Starting from a blank sheet of paper, we began the search for solutions, speaking to many people, reading recommended books and researching on Google. It quickly became apparent that there were two routes to achieving what we wanted:

- A collection of standalone packages, each with a monthly license fee. Each package would do part of what we wanted, but Bensons with the task of integrating the outputs; or,

- A single, integrated solution where all the functionality we needed (and more) was included in a single package.

The later entailed more work in the implementation stage, but the short term pain would be mitigated by the long term benefits that we would go on to reap.

Having decided upon the ERP approach, we then evaluated a number of packages and implementation approaches. Here it is important to take account of the maturity, capability and needs of your company. Going from paper and spreadsheets to a full blown Oracle implementation delivered by one of the big five consultancies probably isn’t the right answer for a 40 person SME in West Yorkshire. After considering many options and viewing the end product in operation at other manufacturers, we opted for the E-max Systems solution, an affordable ERP system optimized for SME manufacturers, with many features which could be tailored to our requirements.

Agree how to deliver the implementation

The implementation approach is an important consideration, based on our experiences there were two routes to a working system:

- Pay the ERP provider to do the bulk of the work for you, an expensive approach which can limit your exposure to the workings of the system; or,

- Do the implementation heavy lifting in-house under the guidance of the ERP provider.

At Bensons we opted for the later approach, establishing a core team drawn from the different business functions who would need to use the system. We also documented our objectives in a project charter which became our ‘North Star’ when we periodically got lost in the weeds. Note that an important part of the charter is defining what you are not going to do, as well as what you are going to do, this helps to eliminate scope creep.

Holiday reading - summer 2018

Within the core team we established two key roles

- Super-user. The go to person on site who understands what the system does, why and how. They are the triage person for issues during the operation of the ERP system, and the focal point for improvements; and,

- Project Sponsor. The senior business leader who ensures time and resources are available to deliver the project, and that the team focuses on delivering the benefits required from the EPR system.

The two people cannot be the same person.

Whilst doing much of the work in house was labour intensive at times, it gave us the knowledge of how and why our solution worked the way it did, it also gave us ownership over the data that we put into the system. Data cleansing before you begin is vital if you want to have a robust, reliable system that outputs the insight that you need. Doing the cleansing inhouse ensure that you get what you need and know it is correct.

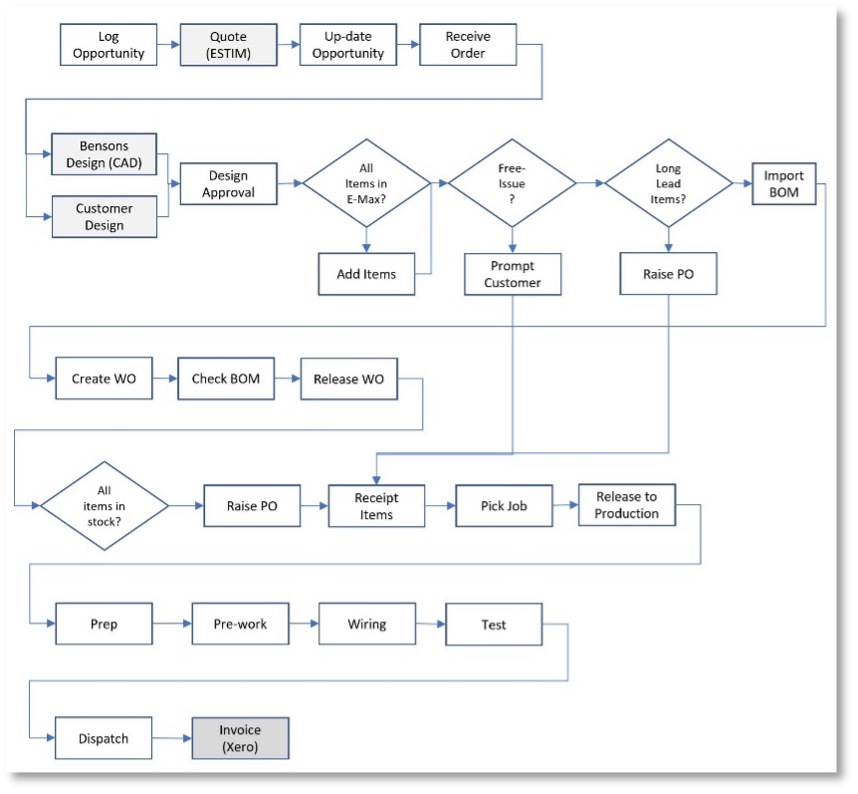

Invest time in building a plan

None of the team at Bensons had implemented an ERP solution before, so we worked closely with the implementation lead from E-max to establish what tasks needed to be completed, and importantly their interdependencies. Doing this as a team highlighted our gaps in knowledge, data and processes. This resulted in much effort being devoted to mapping our processes to ensure optimal product (and data) flows in the business.

Top Level Process Mapping

At the end of this stage we had a plan and milestones which guided the implementation activity. Having established a core team, we then worked collaboratively, holding regular meetings focused on progress against agreed actions and objectives.

Transition to using the ERP solution

There are two approaches to transitioning to the use of an ERP system:

- Big Bang – At a given time and date, legacy systems are turned off and the business relies on the ERP.

- Phased Implementation – Transition the management of processes from legacy to ERP one by one.

We opted for the later approach, in many cases running the ERP system alongside legacy processes to ensure that we had full confidence it was working.

A key learning here was to define the criteria which, when achieved, meant that we would transition fully to the ERP solution. Again, this was done collaboratively as a team and resulted in ten criteria which, when achieved, meant we would collectively take the ‘brave pill’. This helped to give focus on key tasks towards the end of implementation and remove the search for reasons not to do something that was (at the time) a bit scary.

Save until the end

The bonus stage – an ERP system is never finished

After a 'bedding in' period, where you gain familiarity with the system, the ideas for improvement start to flow. Here you start to reap the benefits of a super-user who can take these improvements forward and continuously evolve system performance, functionality and benefits.

What benefits did we accrue?

Whilst the process was painful in places, we would not go back and continue to enjoy the benefits from our ERP:

- We now have a dramatically lower overhead associated with tracking our performance job by job;

- Our stock management has improved such that we are consistently around 98 to 99% BOM completion at the start of each job in production; and,

- During the Covid-19 pandemic and ensuring supply chain melt-down, we were able to manage our stock and purchasing with confidence.

Celebrating ISO9001 Audit Success - and why it matters to our customers

We’re delighted to share that Bensons Panels has successfully passed our latest six-monthly ISO9001 audit, this one had a particular focus on our manufacturing processes and systems.

Five tips for a High-Quality Control Panel Enquiry

At Bensons Panels, we believe that great projects start with great conversations. The early conversations that come at the enquiry stage can shape the outcome and character of the whole project.

Investing in Expertise – The Added Value from Working with Bensons Panels

Choosing the right control panel partner is an important decision, one that can shape your project’s immediate success, but also the ongoing efficiency and reliability of the system that the control panel is integrated into.

Leeds Manufacturing Festival 2025

On 12th June, Bensons attended the Leeds Manufacturing Festival (LMF) annual awards, this year hosted at Leeds Beckett University, to celebrate the champions of the industry.

Need to discuss your perfect Control Panel solution? Simply fill in the form with your details and requirements and we'll be in touch!