Honeywell

Control Panels for Building Management Solutions - Honeywell UK

The Challenge

How to upgrade with minimum disruption to the business

With a reputation for continual improvement and innovation in their

sector, Honeywell are regularly requiring control panel maintenance to

support their critical activities in the Building management solutions

sector. All this needs to be done in the background whilst seamlessly

offering upgrades to their client base.

The Solution

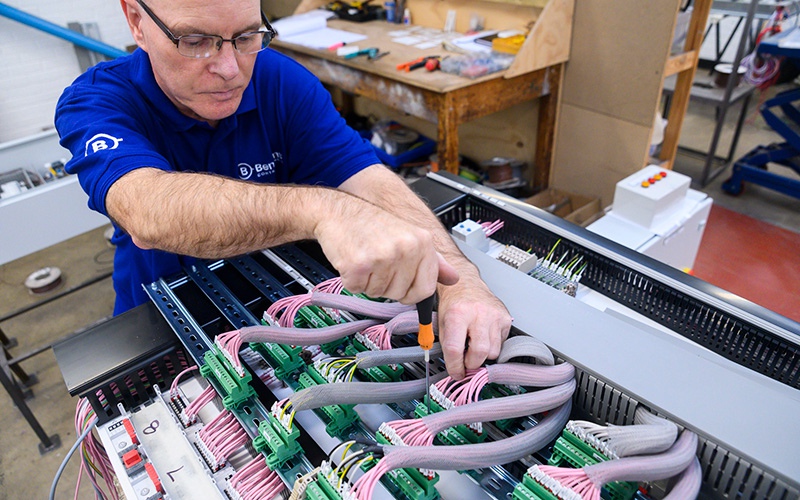

Pre-wired backplates, with swing frame configuration

Several options were considered factoring in cost and operational

impact. The solution was assembled and tested at Benson’s prior to the

fitting at Honeywell sites.

The Result

Cost-effective | Minimal Downtime | Minimised technical risk | Simplified fault finding

The success of the initial project allowed Bensons to carry out 50 similar upgrades at Honeywell sites across the UK

Download Case Study