Waste Management and Waste Disposal Organisation

Developing a Bespoke Control System for a Leading Waste Management and Waste Disposal Company

The Challenge

To develop a unique control mechanism to ensure the company operated consistently and safely.

A system was required to incorporate an extensive control network

with various sensors, actuators and alarms for the safe and effective

processing of batteries. They also required a bespoke multi-architecture

software program to collate and analyse data from the control

mechanisms, plus full control of a battery waste process line.

The Solution

Software development and simulation of the process line to enable operational efficiencies.

Bensons’ development team began by analysing the battery separation

process. The team then conducted research into each machine to determine

which control measures were required. Bensons developed the overarching

software program which would provide the foundation for the entire

network

The Result

Bespoke software with safety and efficiency at its heart.

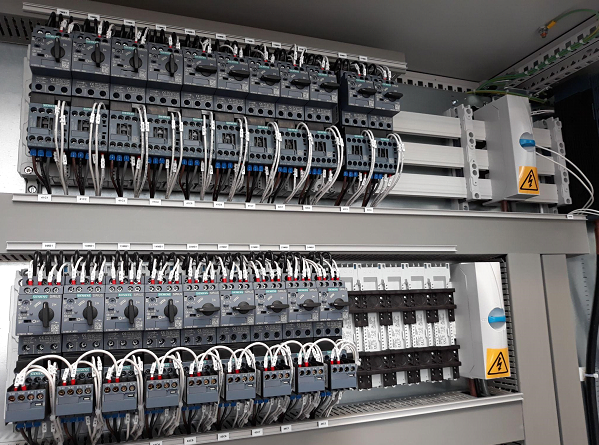

Motor control centre and software system for the safe operation of the battery separation process line

Download Case Study